Neural networks for ultrasonic defect detection

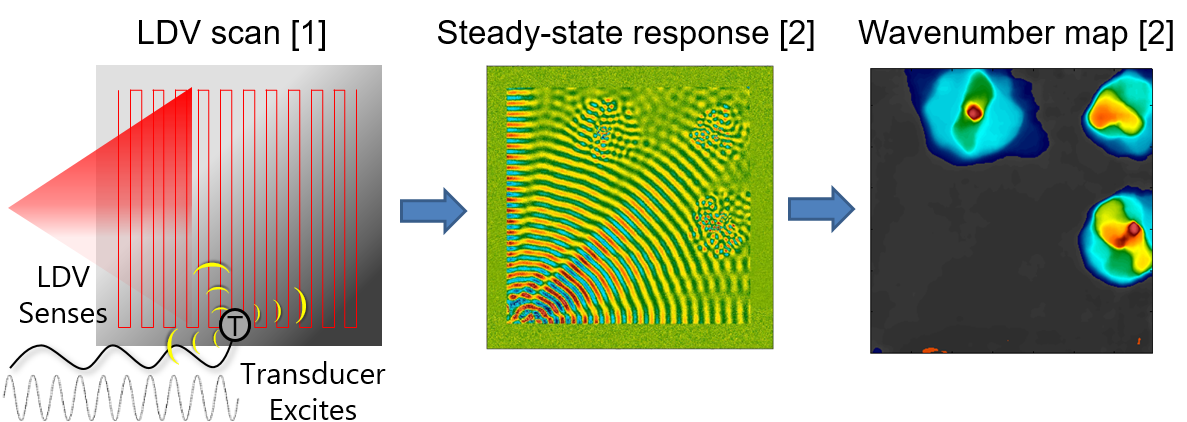

An ultrasonic transducer excites a plate-like structure to steady-state and a laser Doppler vibrometer (LDV) scanner obtains the surface velocity response. The wavenumber of the propagating waves is dependent on local changes in thickness of the plate, which indicates damage such as corrosion, cracking, or delamination. This project involved training a convolutional neural network (CNN) on simulated ultrasonic data to classify plate thickness and detect damages and defects. The CNN performed orders of magnitude faster than traditional processing methods and provided more accurate results.

Fig 1. The Acoustic Steady-State Excitation Spatial Spectroscopy (ASSESS) method.